1. Before starting the pipe bending machine, it should be checked

Is the oil tank filled with hydraulic oil?

Has the hydraulic oil capacity reached the standard position?

Is the hydraulic station water-cooled or air-cooled?

Water cooling requires a water pipe, while air cooling does not require a water pipe, but it is necessary to check whether the air cooling motor can start normally?

Is the fan running?

Is the oil port loose?

Is there any oil leakage at the oil circuit interface?

Are there any oil shortages at the lubrication points of each slider guide rail?

Are the connection points or screws of each mechanical motion mechanism loose?

Is the anti touch device effective and reliable?

2. Is there any noise when restarting the hydraulic oil station system of the pipe bending machine?

Is the direction of motor operation correct? If it is incorrect, an electrician needs to adjust the wiring sequence of the three-phase power supply.

Is the hydraulic system oil pressure within the normal range? Excessive oil pressure can damage hydraulic components. The hydraulic system oil pressure is too low, and the pipe bending machine will not work properly.

3. According to the drawing requirements of the product, select the appropriate diameter and length of the pipe, and first set the various bending parameters and bending angle parameters on the operation screen.

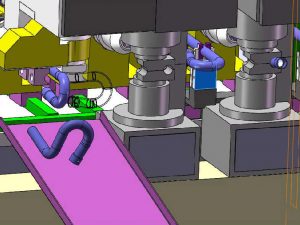

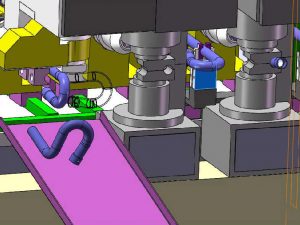

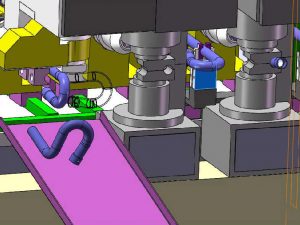

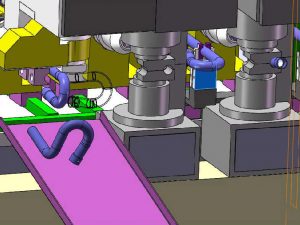

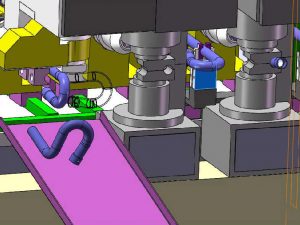

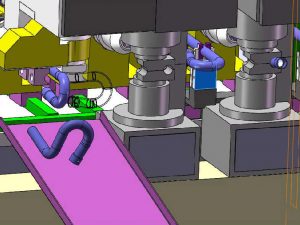

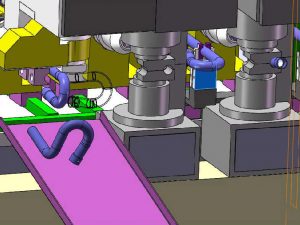

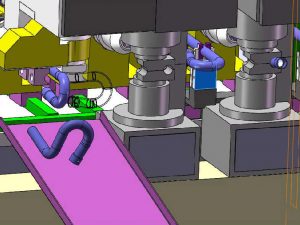

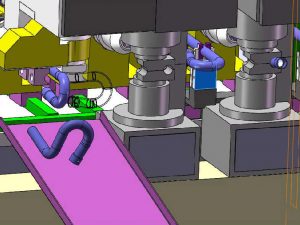

4. Then adjust the mechanical position, length, angle, and other positions of each mold and auxiliary push rod on the pipe bending machine according to the drawings.

5. Adjust the position of the limit switch and adjust the fastening bolts of each guide rail according to the travel of the feeding trailer, so that it can press the pre bent pipe tightly.

6. Adjust the cylinder of the clamping mold according to the parameters on the drawing, and press the pre bent pipe tightly.

7. After adjusting the appropriate positions of each mold and auxiliary pushing fixture for pre bending, the specific operation of trial bending can be carried out. Step on the foot switch and operate the machine to perform bending operations.

8. When abnormal phenomena occur during the bending process, please press the emergency stop button to stop the operation, analyze the cause of the fault until the pipe can be bent normally, and then proceed to the next step of operation. Or if there are safety hazards in the pipe bending machine after inspection, or if the system itself has faults, it is necessary to ask the manufacturer to come and repair it.

9. After the bending test is completed, check whether the product meets the requirements specified in the drawing. If it meets the requirements specified in the drawing, the bending test is successful and the next stage of work can be carried out.